Introduction

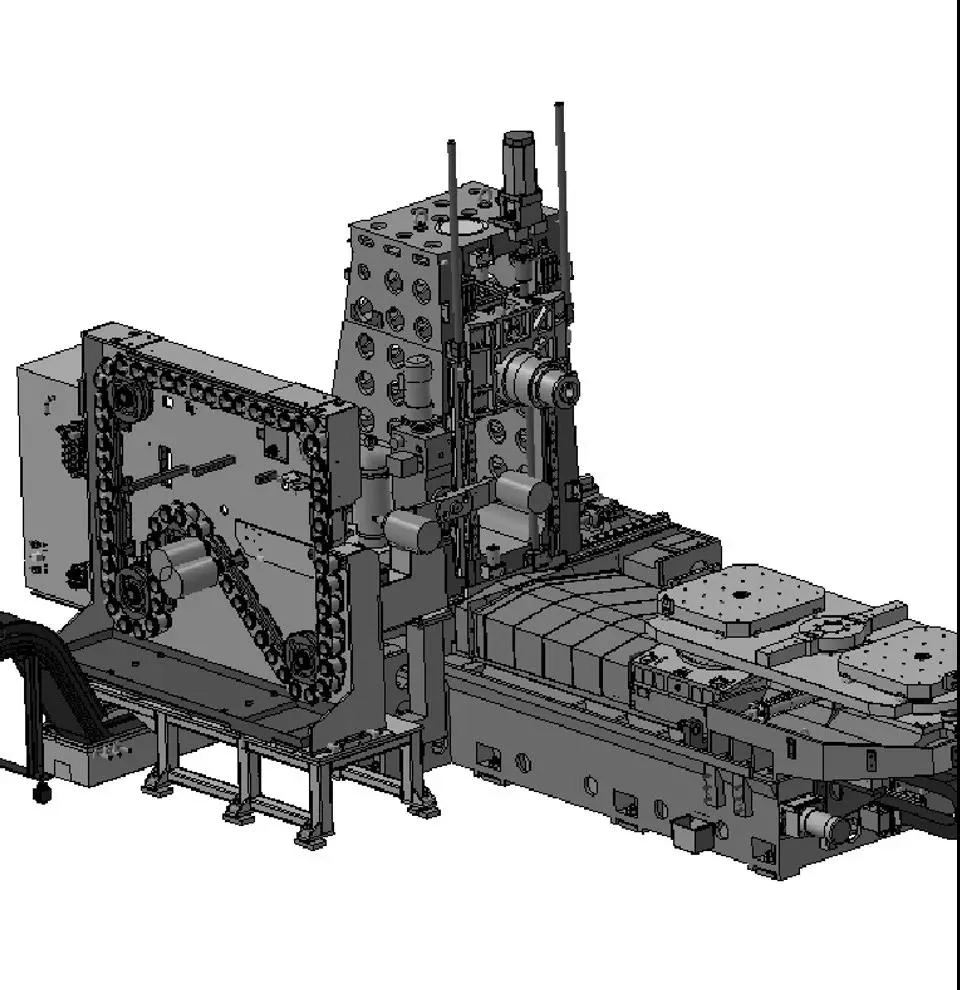

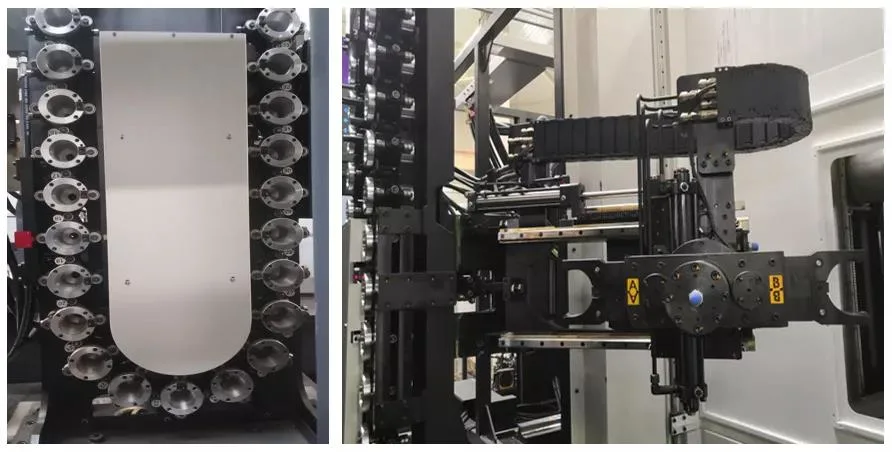

This series horizontal machining center has a T-shaped frame, integrated foundation and large-span, double-wall column. Imported roller guide ways are used in X, Y and Z axes, which ensures high rigidity of the whole machine. The machine features forced-cooling high-speed ball screws that are imported from foreign countries, and forced-cooling directly-mounted main spindle, which ensures machine precision stability. Equipped with world famous controller and high speed configuration, the machine has high controlling accuracy and can meet the requirements of all sectors.

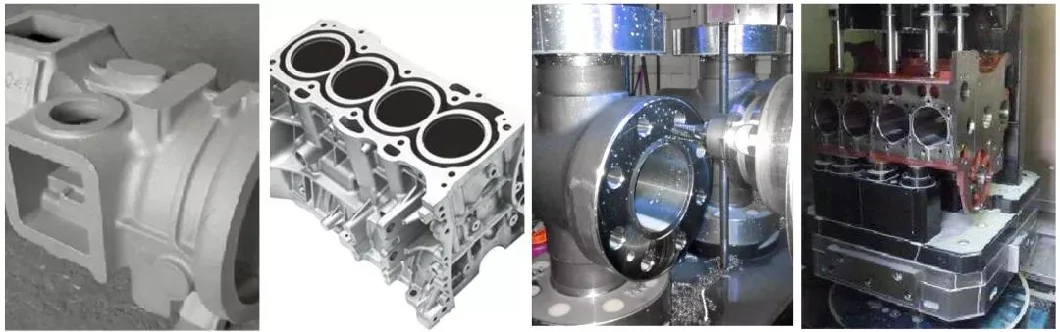

The machine, equipped with double pallet workpiece changer, is suitable for precision machining of dies/molds as well as for multi-face machining of cases, plates, covers and blocks in large batches.

Specifications

| items | Unit | HMC500 | |

| Travel | X-axis | mm | 850 |

| Y-axis | mm | 700 | |

| Z-axis | mm | 800 | |

| Distance from spindle nose to center of table | mm | 70-870 | |

| Distance from spindle center to top of pallet | mm | 75-775 | |

| Table and pallet | Table size ( | mm | 500×500 |

| Indexing of table (deg) | Deg | 360×1°(0.001°) | |

| Type of table | 24-M16 | ||

| Loading capacity of table | kg | 500 | |

| mm | Ф750,H850 | |

| Type of pallet change | Rotating | ||

| Change time of pallet | s | 12 | |

| Number of pallets | 2 | ||

| Height of table from floor | mm | 1150 | |

| Max. load torque of table | Nm | 2250 | |

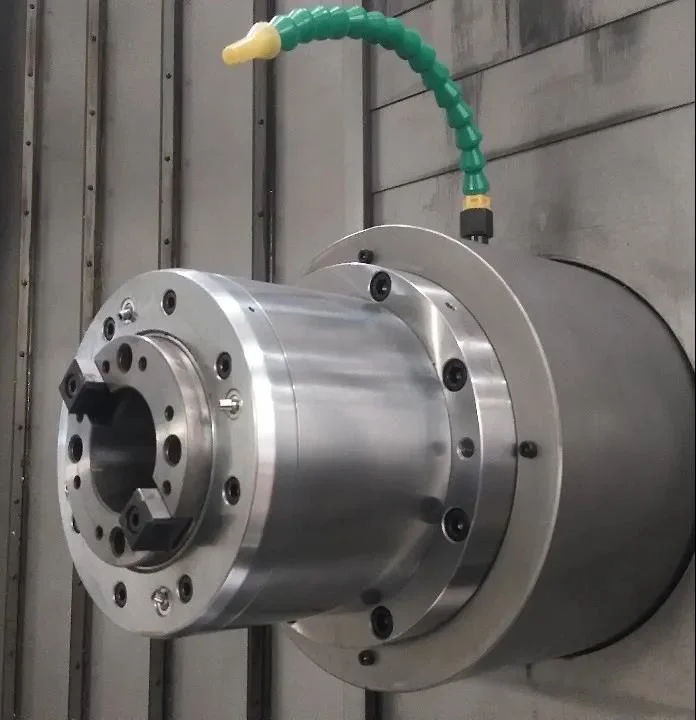

| Spindle | Spindle speed | r/min | 7000 |

| Spindle power | kw | 15/18.5 | |

| Spindle torque | Nm | 95.4/117 | |

| Taper hole | BT50 | ||

| Spindle cooling | Forced cooling | ||

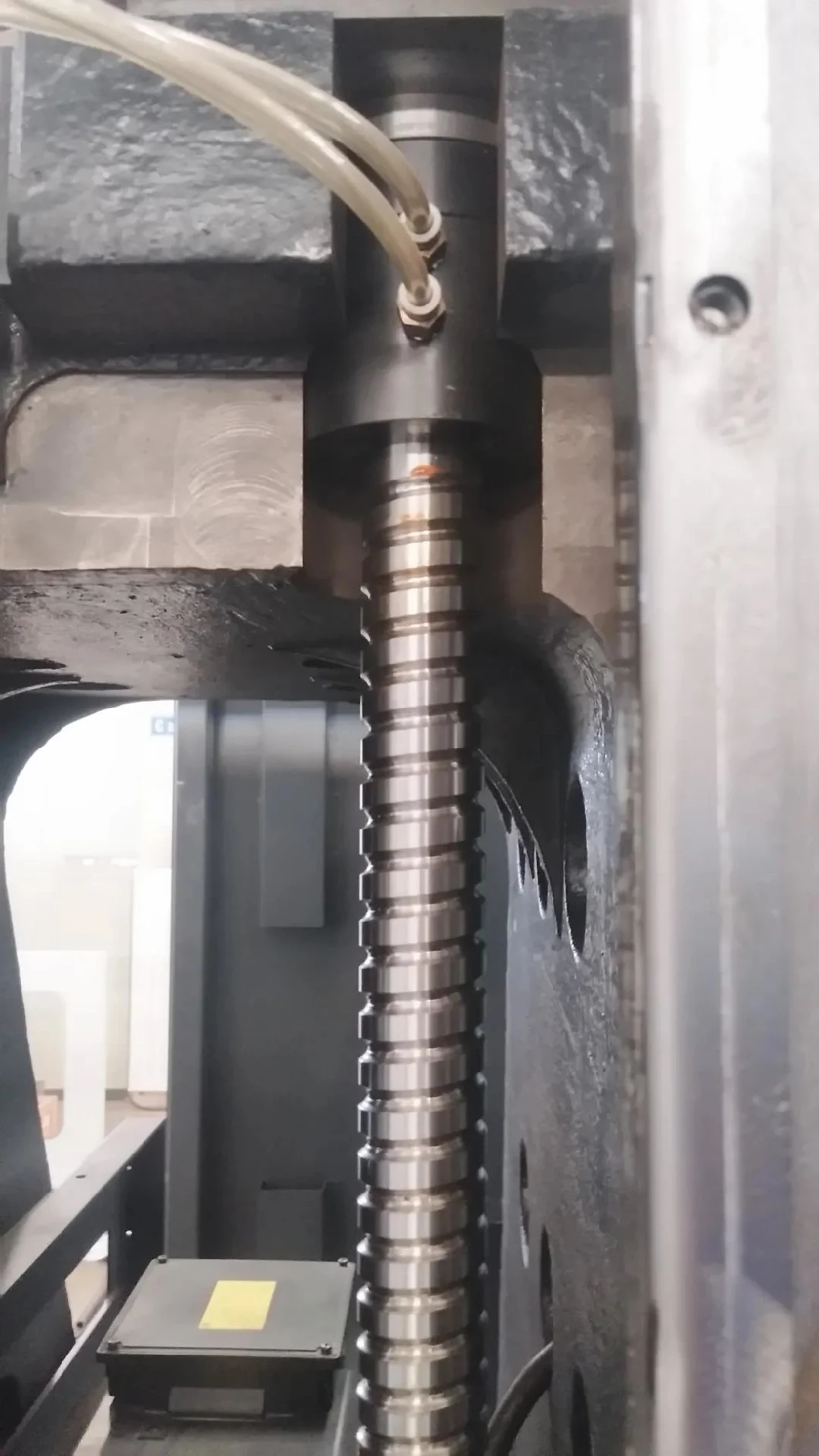

| Feed | Guide way | Linear roller ways | |

| Torque of feed motor X/Y/Z | Nm | 30/22/22 | |

| Rapid traverse X/Y/Z/B | m/min | 36/36/36 | |

| Cutting feed X/Y/Z/B | m/min | 12 | |

| Cooling of screw | Forced cooling | ||

| Encoder of three axes | Optional | ||

| Tool changer | Capacity | pc | 40 standard |

| Tool change type | Manipulator | ||

| Tool selection type | Random, Bidirection | ||

| Max. weight of tool | kg | 25 | |

| Max. diameter of tool (occupied/empty adjacency) | mm | 125/250 | |

| Max. length of tool | mm | 350 | |

| Type of tool shank | MAS403 BT50 | ||

| Type of drawbar | MAS403 P50T-1(45°) | ||

| Tool change time (T-T/C-C) (S) | s | 3.5/7.5 | |

| Accuracy | Bidirectional positioning | mm | 0.012 |

| Bidirectional positioning in case encoder | mm | 0.006 | |

| Bidirectional repeatability | mm | 0.008 | |

| Bidirectional repeatability in case encoder | mm | 0.005 | |

| Indexing accuracy of table | " | 15 | |

| Repeatedly indexing accuracy of table | " | ±3 | |

| Others | NC controller | FANUC 0iMD standard | |

| Air source | MPa | ≥0.5 | |

| Capacity of cutting fluid tank | L | 500 | |

| Power source | kw | 50 | |

| Dimensions of machine | mm | 5150×3845×2975 | |

| Weight of machine | kg | 20000 | |

It is widely used in aerospace, internal combustion engine, new energy vehicle gearbox, engine, mold and other manufacturing industries.