- Main specifications and parameters

| Machine type | SP-1325 | ||

| Worktable | Worktable size | 1100*2500 | mm |

| Load bearing of worktable | 5000 | kg | |

| T-slots(N x M) | Center: 7-22x150 | mm | |

| Products Range | Longitudinal travel X axis | 2600 | mm |

| Cross travel Y axis | 1400+160(tool changing) | mm | |

| Vertical travel | 800 | mm | |

| Distance between spindle nose to worktable surface | 150-950 | mm | |

| Distance between two columns | 1400 | mm | |

| Spindle | Spindle taper | BT50/Φ190 | |

| Spindle motor | FANUC β iIP30/6000 15/18.5KW | ||

| SERVO MAIN MOTOR RATED OUTPUT TORQUE | 143 | Nm | |

| Speed range | 40-6000(direct) | rpm | |

Feed | Rapid feed speed X axis | 10 | m/min |

| Rapid feed speed Y axis | 10 | m/min | |

| Rapid feed speed Z axis | 10 | m/min | |

| Tool Magazine | Tool magazine model | MANIPULATOR | |

| Capacity | 24 | T | |

| Max. Tool diameter | Φ110/200 | mm | |

| Max. Tool allowable weight | 18 | kg | |

| Max. Tool allowable length | 300 | mm | |

| Tool change time | 3s(T-T) | ||

| Tool change way | Arbitrary | ||

| Max. Cutting feed speed | 8000 | mm | |

| Accuracy | Positioning accuracy | ±0.03 | mm |

| Re-positioning accuracy | ±0.018 | mm | |

| Accessories | Dimension of three axis guide rail(XYZ) | X axis 2-45# roller type linear guideway | |

| Y axis 2-45# roller type linear guideway | |||

| Z axis box type guideway | |||

| Diameter of three axis screw(XYZ) | X axis Φ6316 | ||

| Y axis Φ5016 | |||

| Z axis Φ5016 | |||

| MACHINE ELECTRIC CAPACITY | 63 | KVA | |

| MACHINE COMPRESSED AIR | 6 | kg/cm2 | |

| POWER REQUIREMENT | 380V±10% 50Hz | ||

| Machine weight | 23000 | kg | |

| Machine dimension | 7800×5500×5000 | mm | |

2. Standard accessories

| Item | Standard accessories | |

| 1 | Main driving system(include spindle, main motor etc) | |

| 2 | FANUC CNC system(include main motor, servo motor, driver, amplifier etc) | |

| 3 | Three axis servo drive system( linear guide, ball screw etc) | |

| 4 | Main part(include base, worktable, column etc) | |

| 5 | Hydraulic balancing system(include balance cylinder, air reservoir, pressure pipe etc) | |

| 6 | Automatic lubrication system( include lubricant pump, allotter etc) | |

| 7 | Automatic chip conveyor(include 2 screw type and 1 chain type) | |

| 8 | X,Y axis internal protection |

3. Optional accessories

| Item | Optional accessories | |

| 1 | controller: SIEMENS 828D or MITSUBISHI | |

| 2 | chain type tool magazine with 32T | |

| 3 | Heidenhain linear encoders(three axis) | |

| 4 | spindle inner cooling or high pressure water pump | |

| 5 | Tool setter(RENISHAW) | |

| 6 | Taiwan GTP double speed gearbox | |

| 7 | Taiwan brand fourth axis | |

| 8 | Right-angle milling head |

Any other specific accessories you want to change, kindly contact with us directly. We also can supply following service if you need:

- Customize your machine shield color.

- Supply the fixture scheme for your work piece.

- Supply the processing beat scheme for your work piece.

- Supply the tool selection scheme.

- Offer the machine frame or other main parts separately.

3.COMPANY PROFILE

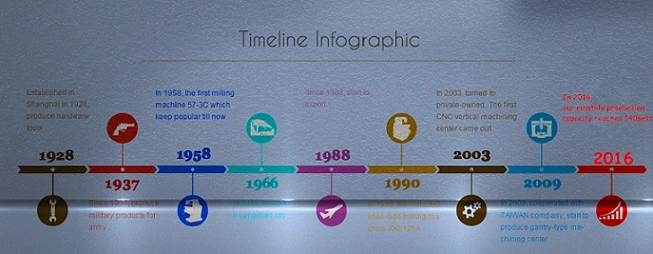

In 1928, Huangshan Wannan Machinery Co., Ltd. established in Shanghai and started with producing hardware tools. Then due to the war, it supplied the military products for the army and developed the first milling machine in 1957. The model is 57-3C which is still sold today. In 2003, we become private-owned and devoted ourselves to the CNC milling machine industry.

With decades of years of development, we now become one of leading manufacturers in China in metal working industry. With continuous updated models every year, our wide range products can meet different market requirements which include most complete models of conventional milling machine, vertical machining centers, and also horizontal machining center, double column machining centers.

Cooperated with site management consultant agent, we devoted ourselves to create a clean and neat working environment. We firmly believe a good environment can inspire workers to make good machines.

Now we have 400 employees. Some of them spent more than 30years here and grow up together with company. Now they are important role in technical research and developing department, inspection department and assembly line due to their professional experience.

Our boss values a lot on young people and put them on management position. He believes YOUNG means "Aspiring, Brilliant, Creative, Dynamic" which can take big change on us such an old historic company.

4. WHY CHOOSE SINO?

Compared with most CNC machine suppliers, we have following advantages:

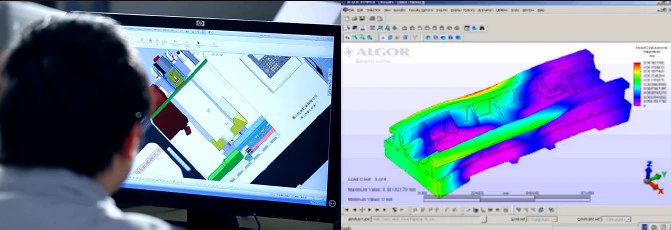

- Independent research and develop ability

2. On-site parts processing

We process all casting parts in our own workshop where equips with five axis CNC machining centers from OKUMA, double-column machining center from NICOLÁS CORREA, and other CNC boring and milling center etc.

- ISO quality control system and 6S site management.

- Standard machine delivery is within 30days.

- Offer flexible procurement plan according to customer's requirements.